Progress report - ESR 6: Sharjeel Ahmed Khan

date: May 08, 2022

category: News

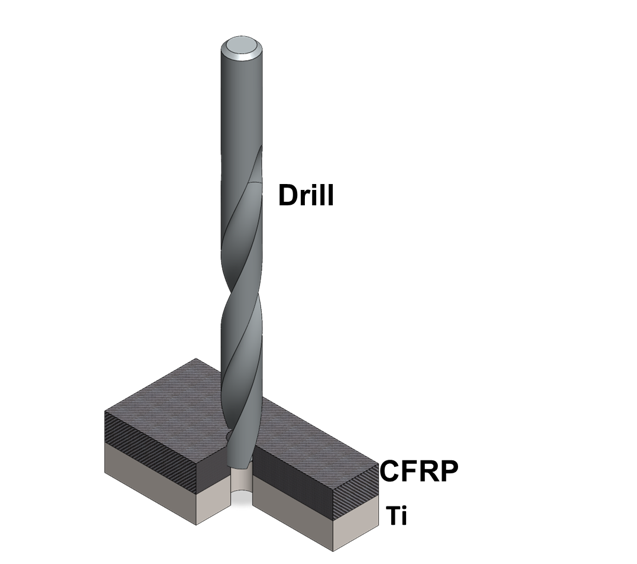

Sustainable and environmentally friendly drilling of CFRP-Ti stack by DLC coated Drills.

With the increased demands for improved fuel efficiency and environmentally friendly alternatives the use of light weight composite structural parts for the aerospace industry is rapidly growing. CFRP-Ti stacks are gaining popularity due to their high strength to weight ratio, good corrosion resistance and excellent load bearing capabilities for structural components like aircraft ribs ad spar. However, the machining/drilling of such material combination is quite difficult as both materials are characterized as difficult-to-machine materials. Usually, WC-Co tools with different coatings were employed to reduce wear of tool and improve surface quality of machined region. Among different coatings, Diamond like carbon coatings (DLC) have high wear resistance, good hardness and low COF and could improve the wear resistance of tool and the surface quality of machine region. However, the adhesion of these coatings with the surface is low due to high internal stresses of the DLC coatings. The initial surface roughness of the substrate could influence the behaviour of the DLC coatings. During the progress meeting, phase-1 of the research regarding the effect of the substrate surface roughness on adhesion and tribological properties of DLC-Ne coatings deposited in HiPIMS were presented. The DLC coatings were deposited on WC-Co substrates having different degree of surface roughness. The analysis includes the load bearing capacity and adhesion of coatings; reciprocating tribological test against steel summarizing results on COF, wear of substrate, wear of counterbody; SEM analysis of the wear scars and counter body. Moreover, preliminary results of the DLC coatings against Titanium (Ti) were also presented to understand the tribological performance of the DLC coatings during machining of titanium.