Progress report - ESR 12: Mobeen Haneef

date: May 20, 2022

category: News

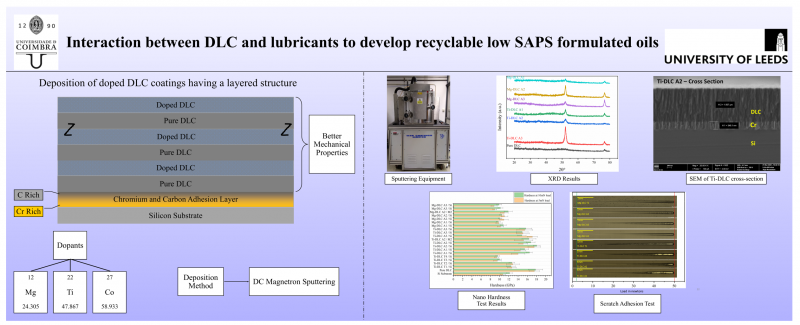

Interaction between DLC and lubricants to develop recyclable low-formulated oils

In this research work, non-layered DLC-M (M = Ti, Mg) and multi-layered DLC/DLC-M coatings were deposited by DC magnetron sputtering. A chromium-carbon gradient interlayer was deposited prior to the DLC-M coatings to improve their adhesion to the substrates. The deposited DLC coatings were thoroughly characterized by scanning electron microscopy (SEM), energy dispersive x-ray spectroscopy (EDX), x-ray diffraction (XRD) in grazing incidence mode, scratch, and nanoindentation testing. SEM images of surface and cross-section showed that DLC-M coatings had granular surface morphology (typical morphology of DLC coatings) and thicknesses from ≈1.2µm to ≈1.5µm. The titanium and magnesium dopant concentrations varied from 8.2 to 2.7, and 11.0 to 4.3 (at. %), respectively. X-ray diffraction patterns confirmed that the deposited coatings are amorphous. Only diffraction peaks from the chromium interlayer were detected. Hardness testing showed that layered doped DLC/DLC-M coatings have better mechanical properties (average hardness and elastic modulus were recorded as 16 GPa and 172 GPa for DLC-Ti and 10.5GPa and 130 GPa for DLC-Mg, respectively) as compared to non-layered doped DLC coatings. A scratch test was used to evaluate the adhesion of coatings with substrate qualitatively, the layered DLC coatings showed better adhesion as compared to non-layered DLC coatings.